Classification of Paper Bags

2025-06-28 11:13Classification of Paper Bags

Classification of paper bags: There are many types of paper bags, including handbags, file bags, envelopes, clothing bags, food bags, shopping bags, and gift bags. They can also be classified according to materials: kraft paper bags, white card paper bags, copperplate paper bags, and special paper bags...

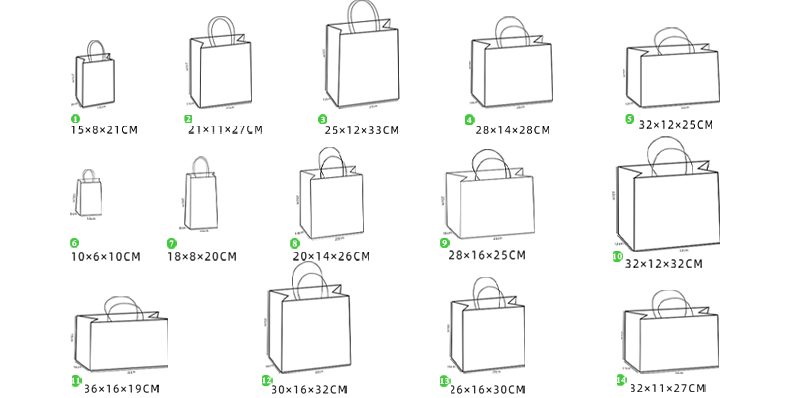

What are the common sizes of paper bags?

According to height x width x wall width, in units of MM, there are: 130*90*30, 150*100*30, 150*110*30, 190*135*50, 200*145*50, 200*150*50, 300*200*60, 320*230*60-70, 320*240*60-70, 390*290*60-80, 440*320*60-80, 450*340*60-80, 600*420*80-100, 650*450*80-100, 700*480*80-100. Of course, you can also design other sizes based on the characteristics of your company's products.

The common materials used for paper bags:white card paper, kraft paper, black card paper, copperplate paper and special paper.

1.Advantages of white card paper: It is sturdy, relatively durable, has excellent smoothness, and the printed colors are rich and full. For paper bags, 210-300 grams of white card paper is commonly used, and the most frequently used type is 230 grams white card paper.

2.The material characteristics of copperplate paper: It has excellent whiteness and glossiness, which enables the pictures and scenes to present a three-dimensional effect during printing. However, its firmness is not as good as that of white card paper. The thickness of copperplate paper commonly used for paper bags ranges from 128 to 300 grams.

3.Advantages of kraft paper: It has high toughness and firmness, and is not prone to tearing. Kraft paper is generally suitable for printing on single-color or two-color paper bags with less color. The commonly used sizes are: 120-300 grams.

4.Advantages of black cardstock: It is sturdy and durable. Its color is black. The main drawback of black cardstock is that it cannot be printed in colors, but it can be used for gold stamping, silver stamping and other processes.

Paper bag printing has a production process:

1.The plate-making machine is the first step in making paper bags. The first step is to make a negative copy of the designed pattern of the paper bag, obtain a negative image (film), and then bring it to the plate-making machine for exposure.

2.Cutting machine. Take the paper specified by the customer and cut it into the size required for the printing of the paper bags. As shown in the table below, cut approximately 10,200 sheets. Cutting an extra 200 sheets is to avoid waste.

3. The picture below shows our printing machine. The handsome guy in the picture is our printing machine operator. He is currently cleaning the machine to ensure that there are no dirt on the surface of the paper. Then he puts the prepared plates on, and inserts the ink to be printed. This is a series of preparatory work before the printing process.

4.Printing machine, place the printed paper and check whether the cut paper is qualified

5.After all the preparatory work before printing is completed, the machine can be started. The color matching should be done according to the printing color specified by the customer. The color matching is not as simple as we imagine. It requires a lot of time for the workers. For orders with higher requirements, the factory manager has to come and inspect personally. Once the color is accurate, large-scale printing can be carried out. However, the workers still cannot relax. They need to be there to supervise. If the ink runs out, it must be replenished again.

6.After all the preparatory work before printing is completed, the machine can be started. The color matching should be done according to the printing color specified by the customer. The color matching is not as simple as we imagine. It requires a lot of time for the workers. For orders with higher requirements, the factory manager has to come and inspect personally. Once the color is accurate, large-scale printing can be carried out. However, the workers still cannot relax. They need to be there to supervise. If the ink runs out, it must be replenished again.

7.Bagging machine, bagging paper bag

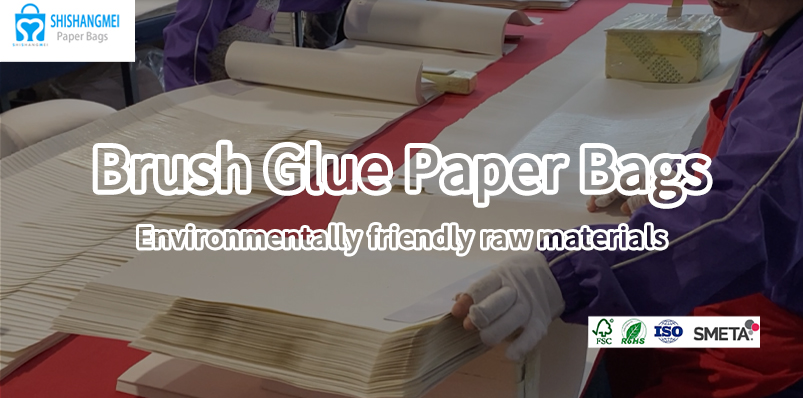

8.When making paper bags, you need to apply glue first before folding them by hand. The amount of glue used should be precisely controlled. Too much glue can cause it to overflow, while too little may result in a less sturdy bag. It still requires experience to get it right.

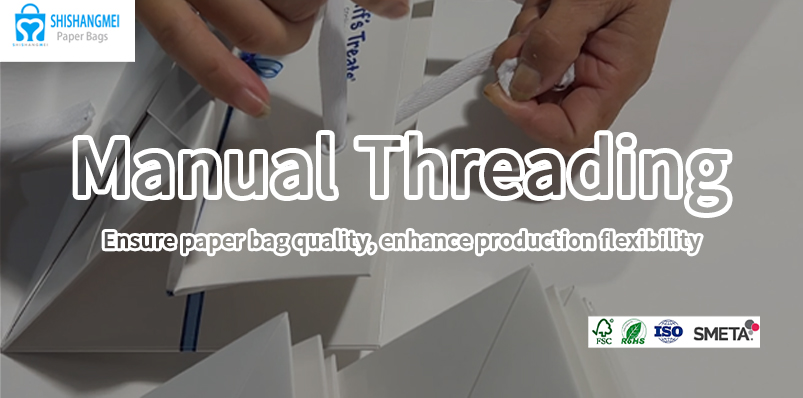

9.Bagging, with the bagging machine available, why is it still done manually? Because for some types of paper bags, their material, process, or size do not allow for machine bagging. They can only be bagged manually. Machine bagging would result in many defective products. For some orders with higher requirements, they are all made manually one by one.

10.The final step is to thread the rope or attach the label. There are numerous types of ropes available, and you can choose and customize them as per your preference. The color of the label can also be customized according to the customer's requirements.