As a customer of paper bags, here are five points you must know!

2025-08-19 14:04As a customer of paper bags, here are five points you must know!

The following is an integration of professional information that is less known to customers in the paper bag industry, covering five key aspects: environmental protection standards, production processes, market trends, cost-profit, and design innovation.

一、Environmental Standards and Sustainability: Policy-driven Invisible Barriers

International Compliance Requirements

The new regulations of the EU's Packaging and Packaging Waste Regulations (PPWR) set specific recycling rate targets (for example, paper packaging must reach 85%), require the establishment of a full life cycle traceability system, and mandate the use of recycled materials.

FSC Certification (Forest Management Council) has become a mandatory condition for exporting to Europe and the United States, ensuring the sustainability of the pulp source. Some enterprises even need to issue special invoices to meet supply chain reviews.

·

Plastic-Free Technology Breakthroughs

Traditional PE laminated paper bags are subject to high tariffs due to their plastic content (such as the EU plastic tax), while the new heat-sealable kraft paper bags achieve oil and moisture resistance through multi-layer fiber densification treatment, and are 100% industrially compostable.

Transparent glass paper bags use plant-based coatings (such as corn starch), which naturally decompose in 180 days, have a transmittance of over 90% and are anti-static, suitable for packaging electronic products.

·

二、 Special Processes and Technologies: High-Barrier Production Details

Material Processing

Glazed Paper is made through a super calendering process, which tightly compresses the fibers, giving it a semi-transparent silk-like texture. Its tear resistance is three times higher than that of ordinary paper, and it is often used for luxury packaging.

Moisture-proof Coating contains organic silicone emulsion, forming a microscopic waterproof barrier, which can withstand humidity changes during cold chain transportation.

Printing and Forming

High-end paper bags use the technology of "water-based ink + UV curing", which avoids solvent residue and supports processes such as hot stamping and embossing. The cost is 15%-20% higher than traditional printing.

The automated production line enables each production line to have a daily output of 100,000 pieces, reducing the proportion of labor costs to below 8%.

三、Market Trends and Consumer Preferences: Underestimated Alternative Space

Policy Benefits

The "14th Five-Year Plan" of China promotes the substitution of paper packaging for plastic. It is expected that the market share of environmentally friendly paper bags will exceed 60% by 2025, and the demand for refrigerated paper boxes in fresh food e-commerce will increase by 15% annually.

Consumer Behavior

Research shows that 70% of consumers in Europe and America are willing to pay a 10%-15% premium for FSC-certified paper bags, but only 20% can recognize the relevant labels.

Small catering brands' purchase volume of custom paper bags can reach 50,000-100,000 per month, with a unit price of 0.7-1.2 yuan, and the profit margin exceeds 35%.

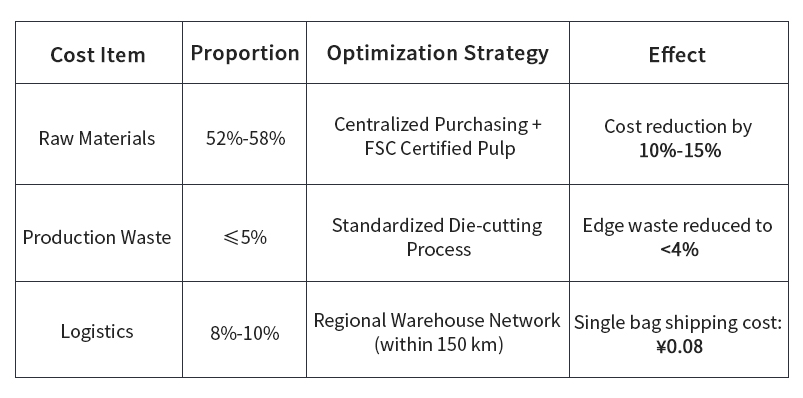

四、Cost Structure and Profit Margin: The Hidden Logic of Cost Reduction

Profit calculation: For a medium-sized factory with a daily production capacity of 50,000 units, the net profit rate can reach 38% - 42%, and the payback period is 4 - 5 months.

五、Design Innovation and Function Expansion: From Packaging to Solution

Intelligent Upgrade

Some brands have attempted to embed NFC chips. Users can scan the code to obtain product traceability information. The cost increases by 0.3 yuan per bag, but the repeat purchase rate increases by 12%.

Environmental paradox

A cotton bag needs to be reused 131 times and a paper bag 3 times to offset the carbon footprint of a disposable plastic bag. Blind substitution may have the opposite effect.

Scene customization

Fashion brands adopt the design of "breathable holes + touch windows" to balance display and dust prevention needs. The accuracy error of the opening needs to be less than 0.5mm

The above information reveals the deep logic of the paper bag industry in terms of compliance, technology and business model. Most customers only focus on appearance and price, while ignoring these key factors that affect long-term competitiveness.